HDPE

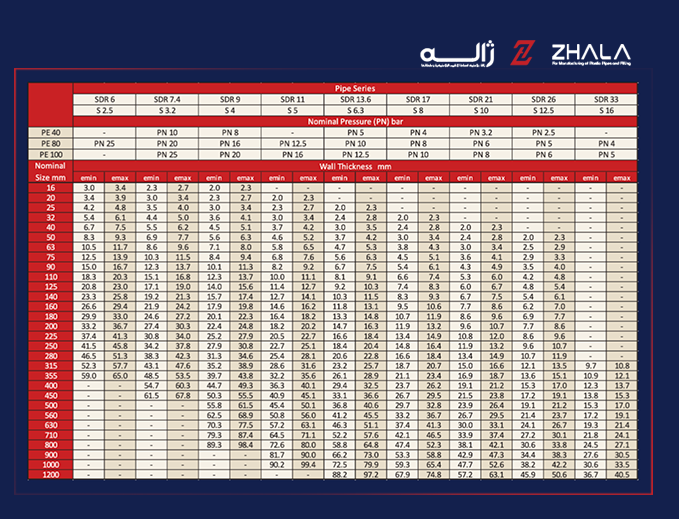

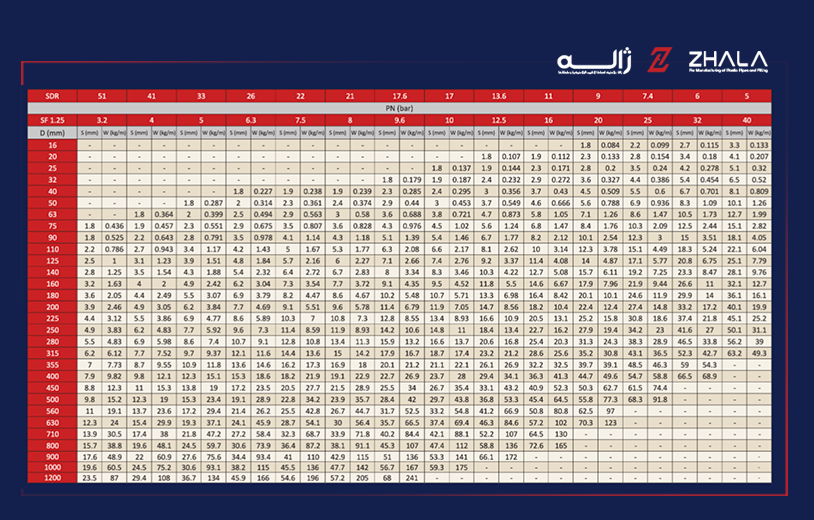

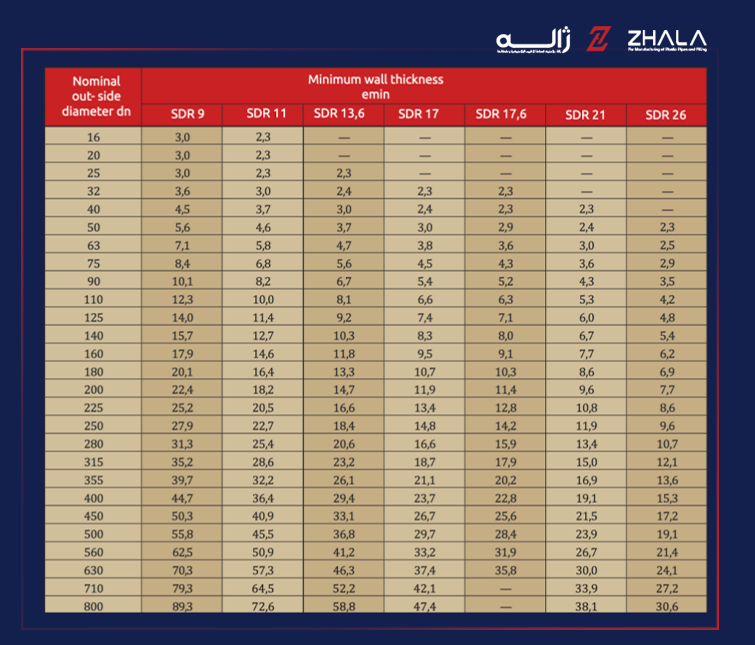

High-Density Polyethylene (HDPE) pipes can be classified, based on the raw materials used in their production, into three types: PE80, PE100, and PE100-RC. Among these, PE100 and PE100-RC pipes are the most widely used compared to PE80 pipes. Thanks to their unique properties, HDPE pipes are an ideal choice for industrial, construction, agricultural, and telecommunications projects, as well as for fluid transportation, especially water and gas. These pipes, in addition to their high durability, ease of installation, and long service life, offer excellent resistance to various environmental conditions and chemicals, and can be manufactured for high nominal pressures.

Potable water

The non-toxic and hygienic nature of polyethylene pipes, along with their non-impact on the quality of transported water, as well as their resistance to pressure, environmental, and thermal conditions, makes them one of the most important choices for drinking water and irrigation systems. Our pipes are available in various diameters and nominal pressures, manufactured from high-quality raw materials using the latest global technologies, and in accordance with international standards.

ISO 4427-2 , IQS 5156-2

DIN 8074

Swerage

Thanks to their high flexibility and resistance to pressure and impact, polyethylene (HDPE) pipes are widely used in drainage systems for both surface and subsurface water control. Their excellent resistance to corrosion and chemicals has made them suitable for various industries, for transporting corrosive fluids or in pressurized sewage networks. These pipes are manufactured in accordance with international standards.

DIN 8074 , ISO 4427-2, ISO 5156-2

Gas

Polyethylene (PE) gas pipes are among the safest products used in the transport and distribution of

natural gas and liquefied petroleum gas (LPG) within urban and industrial distribution networks, in

accordance with international standards such as ISO 4437 and EN 1555.

The use of high-performance polyethylene grades, particularly PE100 and PE100-RC, has significantly

enhanced the mechanical properties, chemical resistance, and service life of these pipes.

In addition, these pipes, with their suitable flexibility, stable behavior under temperature variations,

excellent resistance to localized stresses, cracking, and corrosive soil conditions, as well as wear and

impact resistance, enable the design and implementation of gas networks with high operational safety

and minimal maintenance requirements.

ISO 4437-2

Fiber optic

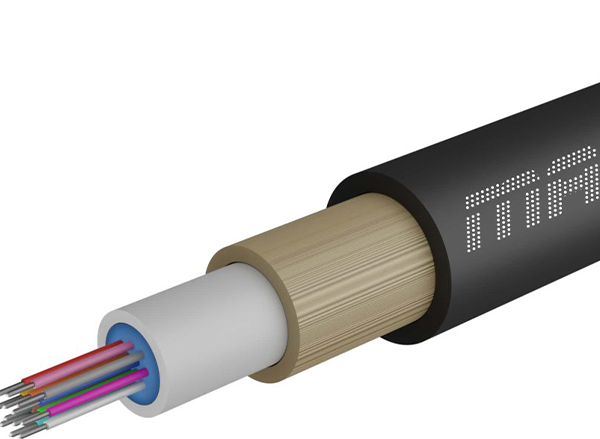

In telecommunications infrastructure projects, PE100 polyethylene pipes are used to safely pass fiber optic and copper cables. The pipes we produce feature a special internal design that helps reduce friction between the pipe and cables during installation, increasing installation speed and work efficiency. These pipes are offered in various diameters, lengths, and operating pressures according to customer requirements. They are also used in projects that require the simultaneous transport of power and telecommunications cables, thanks to their high durability, good safety level, ease of installation, and compliance with required specifications in various applications.

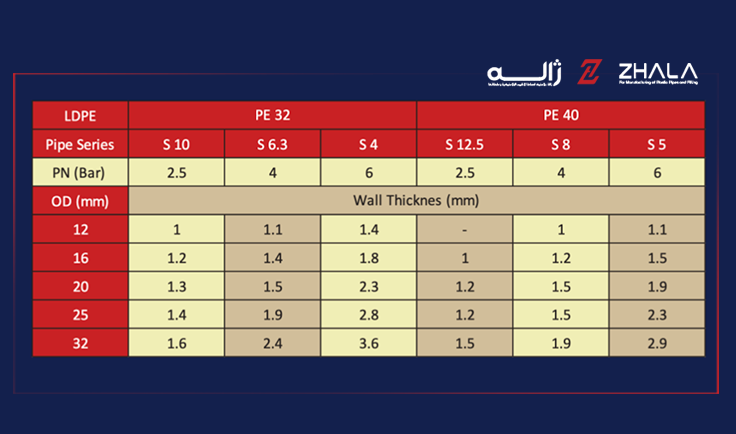

LDPE

Low-Density Polyethylene (LDPE) pipes are the most widely used polyethylene pipes in pressurized

irrigation networks compared to other types of pipes.

• Low-density pipes (LDPE): for low-pressure networks

• High-density pipes (HDPE): for high-operating-pressure networks

LDPE pipes are highly flexible, easy to install, resistant to impact and environmental factors, and

have a long service life, making them an ideal choice for drip irrigation and low-pressure irrigation.

These pipes are produced according to ISO 8796 and ISO 8779 standards, in various diameters and

operating pressures as specified below.

Agriculture

Specification of polyethylene pipes (all dimensions in mm) According to ISO 8779 and ISO 8796 The serial number of the tubes is calculated by (b / b), so that the (BP) is the environmental pressure and (PN) is the normal pressure in the bar Excessive water on the earth’s surface causes great damage to agricultural projects and civil engineering projects, and underground pipes buried at 60 ° to 180 ° are used to collect and extract excess water from gardens, agricultural land, playgrounds, etc. The cracks can be manufactured at different angles according to customer demand.